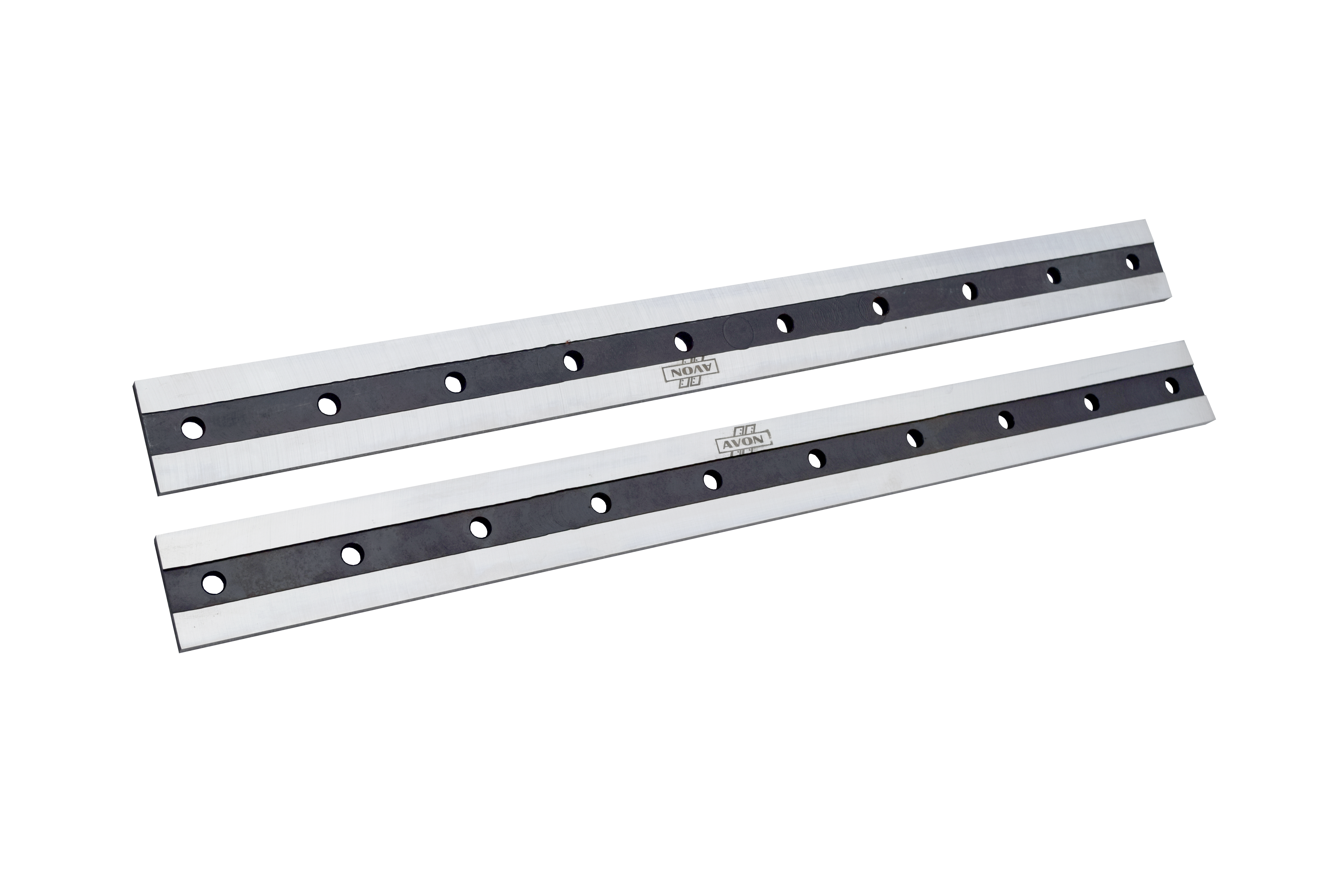

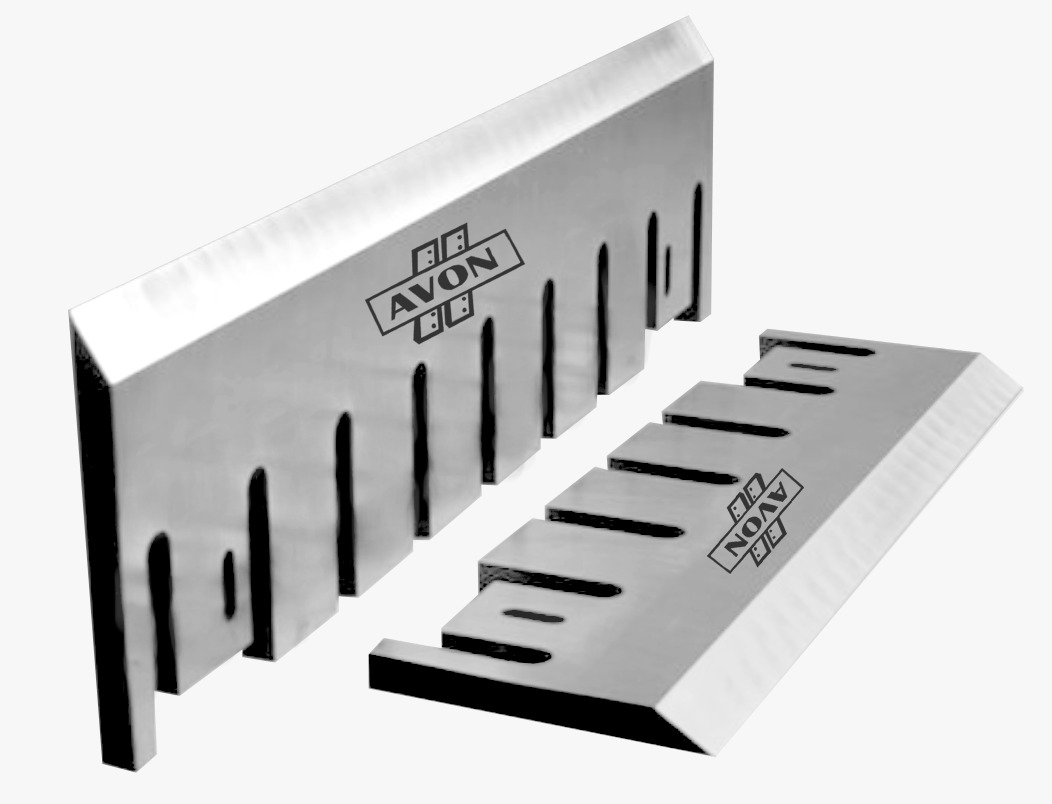

Nothing comes easy but AVON blades surely make it easy

Delivering best so that problem can forever rest.

Events

-

18th Edition INTEC 06- 10 Jun, 2019 Coimbatore, India

-

IMTEX 24- 30 Jan, 2019 Bangalore, India

-

14th Edition Paperex 3-6 dec, 2019 Pragati Maidan

-

Plast India Foundation 05- 10 feb, 2015 Gujarat, India

-

Plast India Foundation 07- 12 feb, 2018 Gujarat, India

About Us

Avon Cutters, since its commencement in 1987, is the leading manufacturer of Industrial Knives and Blades recognised by its quality, integrity, teamwork and experience.

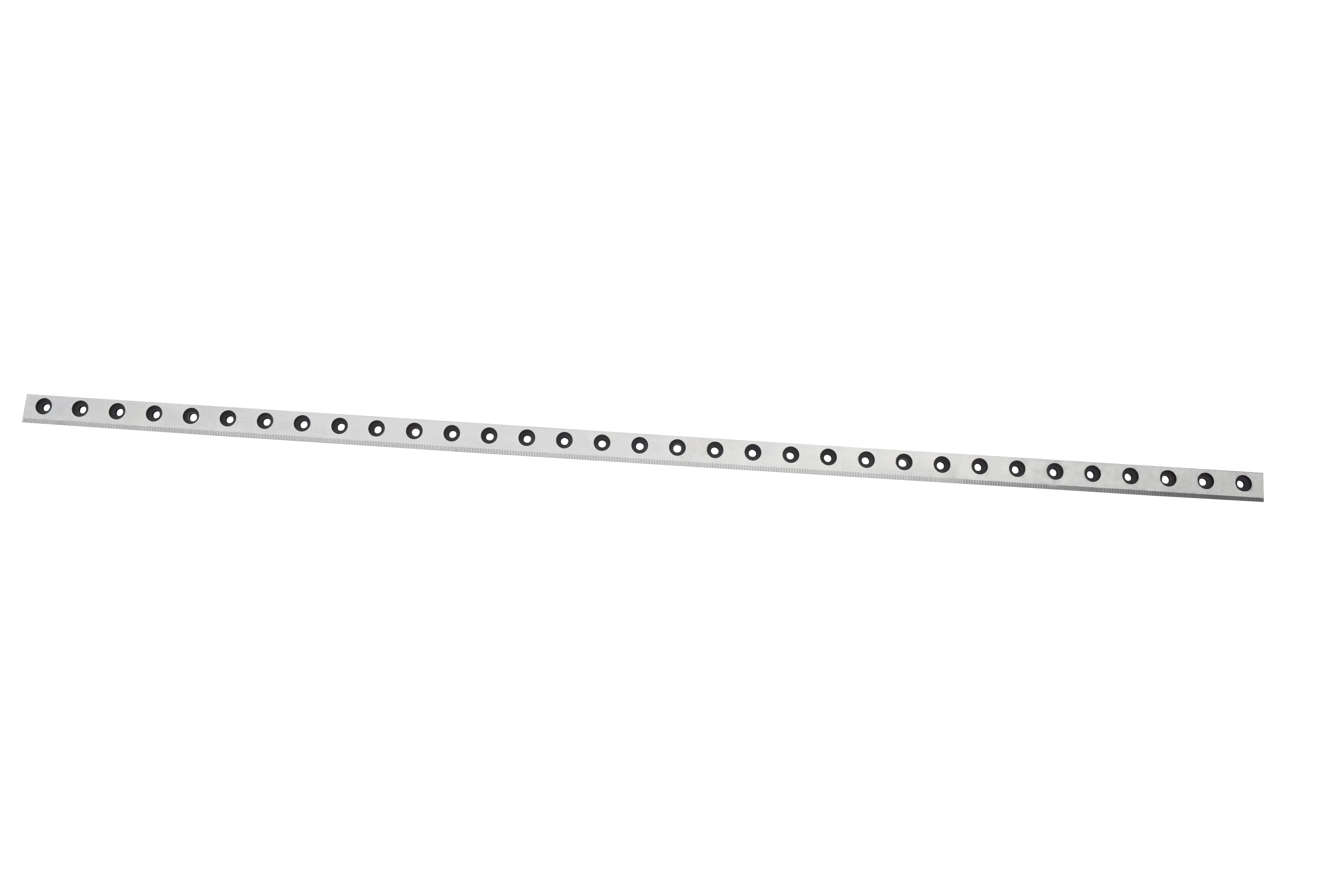

We have insight of over 30 years in manufacturing and supplying of industrial blades for paper, printing, binding, packaging, plastic and metal industries.

The company is exceptional with the most recent in-house technologies to provide effortless performance, clean cutting, and long life which is best suited for a particular application and optimises the output.

We are capable of immediate ‘make to-order’ according to our customer’s sample, image/drawing or sketch.

Owing to the high quality and excellent precision of our cutting blades, we have had been able to acquire the trust of our customers throughout the long term

Checking and persistently observing production processes yields a stable process quality throughout manufacturing for which we have an autonomous Quality Control Department comprising of a profoundly capable and experienced team.

The department has been provided with sufficient modern equipment’s to check the Quality of all processes and carry out stage inspections so that the traceability of any non-conformity can be ensured and corrective and preventive action can be taken accordingly.

We likewise guarantee that the product being conveyed consents to the particulars needed by the client.

Pre-Delivery Inspection is carried out and the records are kept up subsequently, disposing of any such possible non-congruity before the product is shipped.

Our primary objective is to keep the perfect product that takes care of purchaser issues. To accomplish this, we have all in-house advance CNC machining facility to make each product with perfection.

Our infrastructure is divided into various units which empowers us to finish the undertaking more efficiently inside a brief timeframe.

Process

Receiving sample or drawing

We initially start with a machine blade sample/ drawing which is usually provided by our client who has existing machinery with specific knives/blades.

We do Reverse Engineering using high quality measuring instruments and prepare a drawing according to the sample,Then, a metallurgical analysis is done to determine the existing grade of material

Machining

We have well equipped machine shop equipped with high quality VMC machines, Planner , drilling and tapping machines to provide the required shape and profiles to the blades with high accuracy.

Heat Treatment

We have in-house Heat treatment plant equipped with hardening and tempering furnaces having capacity to harden upto 3500 mm length.

We also have a in-house metallurgical lab to check the quality of incoming raw material and final products made by Avon.

Grinding

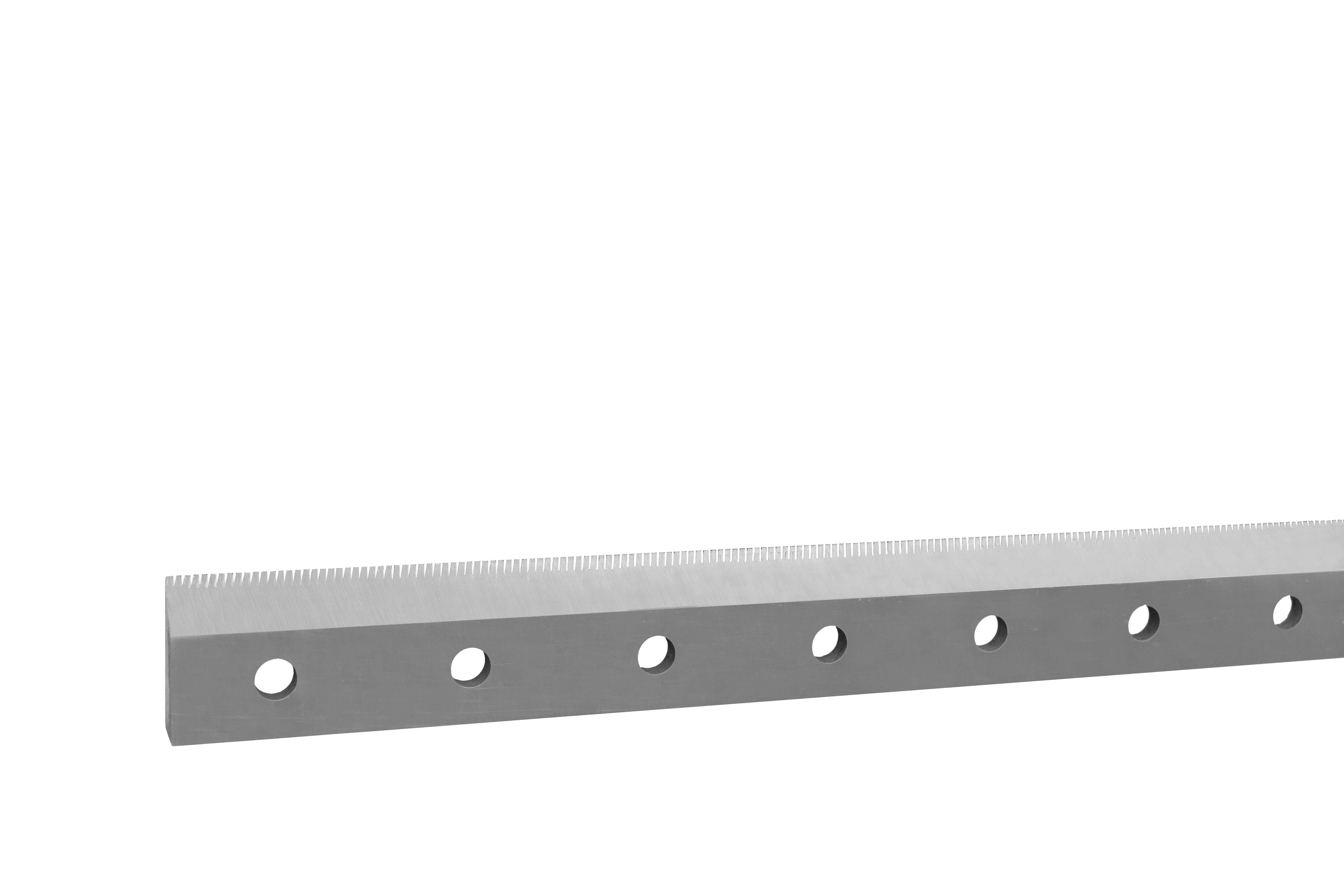

The appropriately tempered blade is ready for grinding and sharpening which begins with straightening and then grinding by high efficiency Gockel make grinding machine with high accuracy and fine finish.

We have brand new Gockel grinding machines with a capacity to grind upto 3500 mm long blades

Inspection

Each and every process has its quality control parameter, however, from time to time a fault slips through, thus it’s important to ensure that every blade has passed a visual & dimensional inspection.

Inappropriate blades are either reworked or disposed off.

Part of our quality control process relies on experience and we rarely have issues with our products.

Packing and Dispatch

We manufacture each blade with great contentment, and are determined to see it showing up at your entryway in perfect condition.

We make sure that each blade is separately wrapped to avoid metal-to-metal contact .

Our external packaging, i.e a wooden box is substantiated as a reliable performer, and they protect the blades on their way from ours to yours.

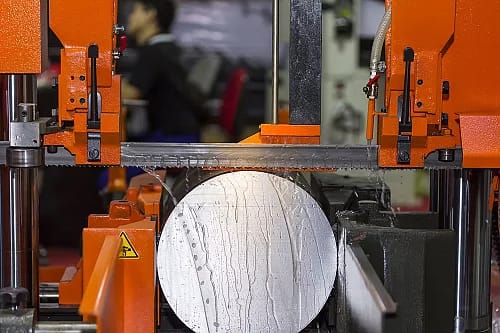

Products

- Paper Industry

- Recycle Industry

- Wood Industry

- Metal Industry

Team

The company is assisted by a group of specialists who are well qualified and have in-depth understanding of the domain that helps in keeping up mutually agreeable relationships with consumers and traders. Groups that help drive the company are purchase team, manufacturing experts, quality examiners, the sales and promoting

Contact

Location:

C-26, Pocket C, Okhla I, Okhla Industrial Area, New Delhi, Delhi 110020

Email:

Call:

+91 9811206522

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)